Build Them Right

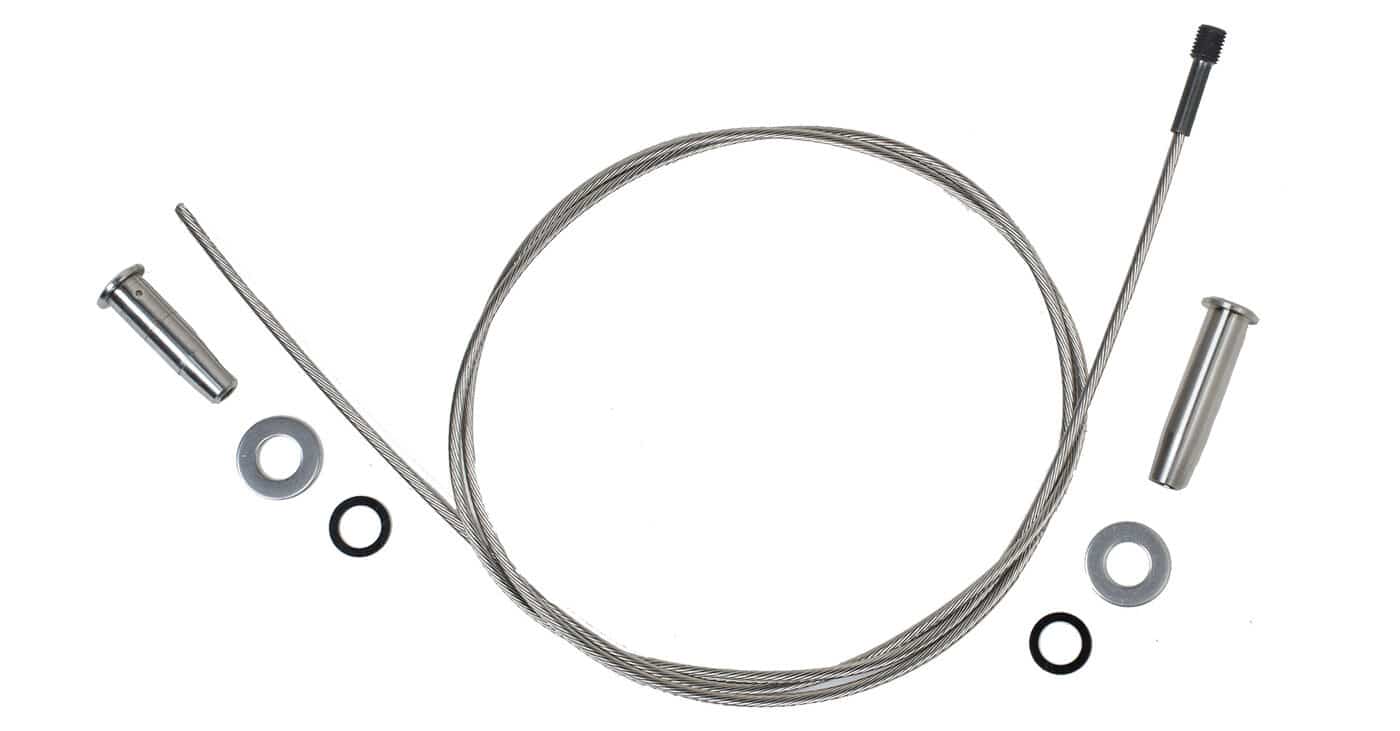

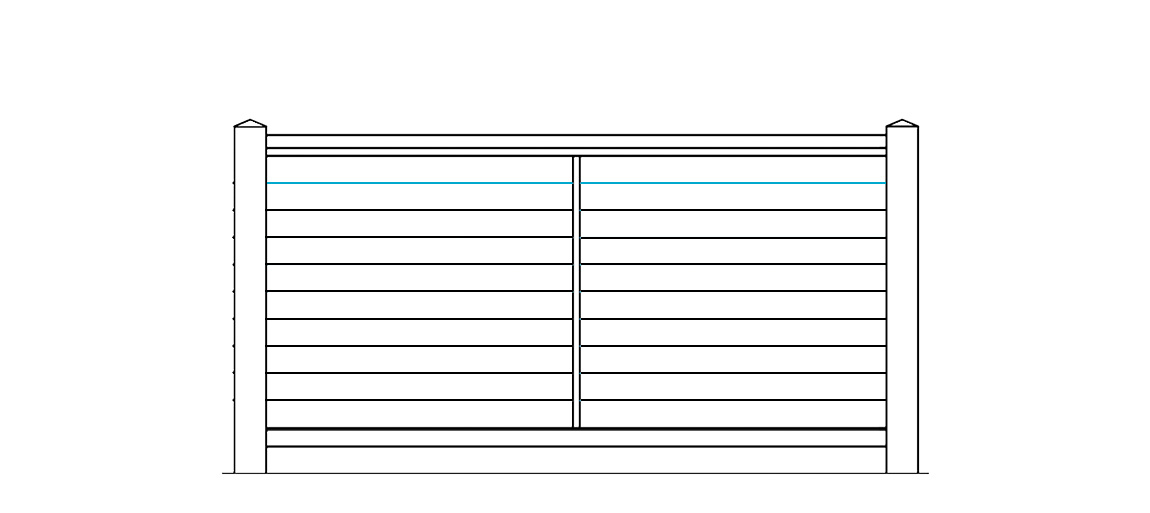

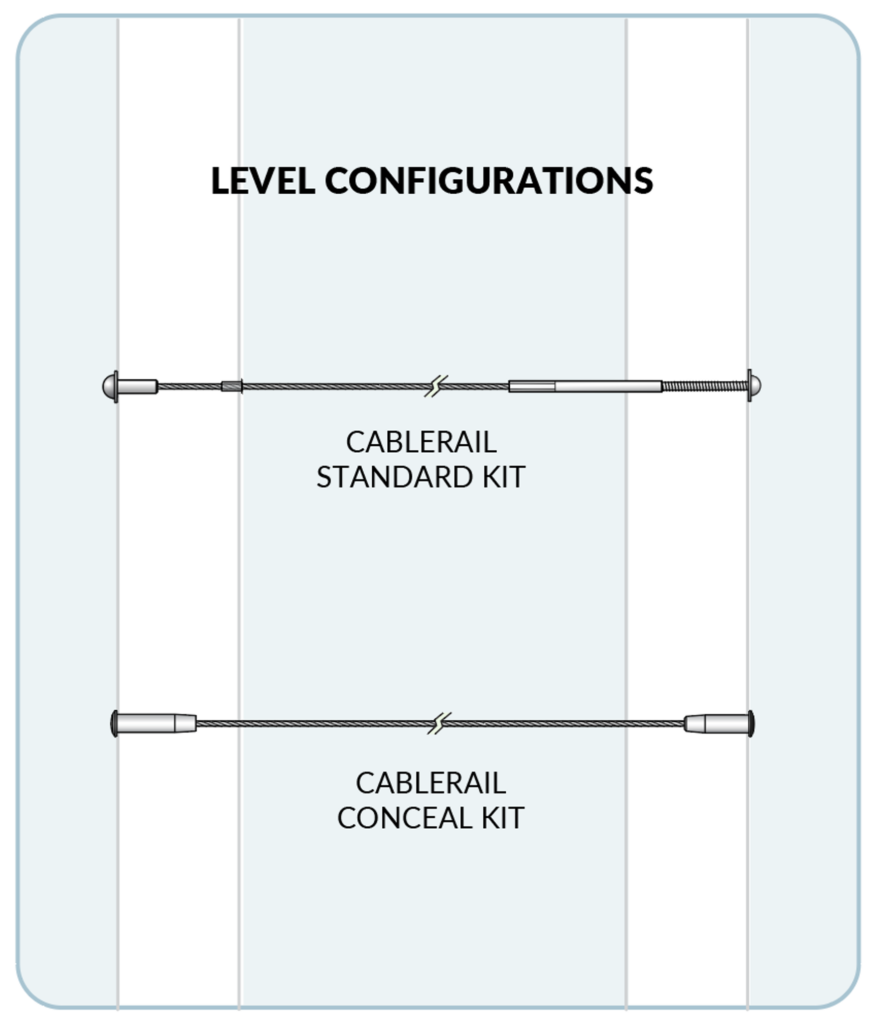

CableRail Kits are the most popular and cost effective solution for wood and metal railing frames, designed for frames where there is access to drill through both end posts, allowing the fittings to anchor to the outer faces of the posts. CableRail Kits include our Quick-Connect® style fittings with automatic-locking jaws making installation a snap.

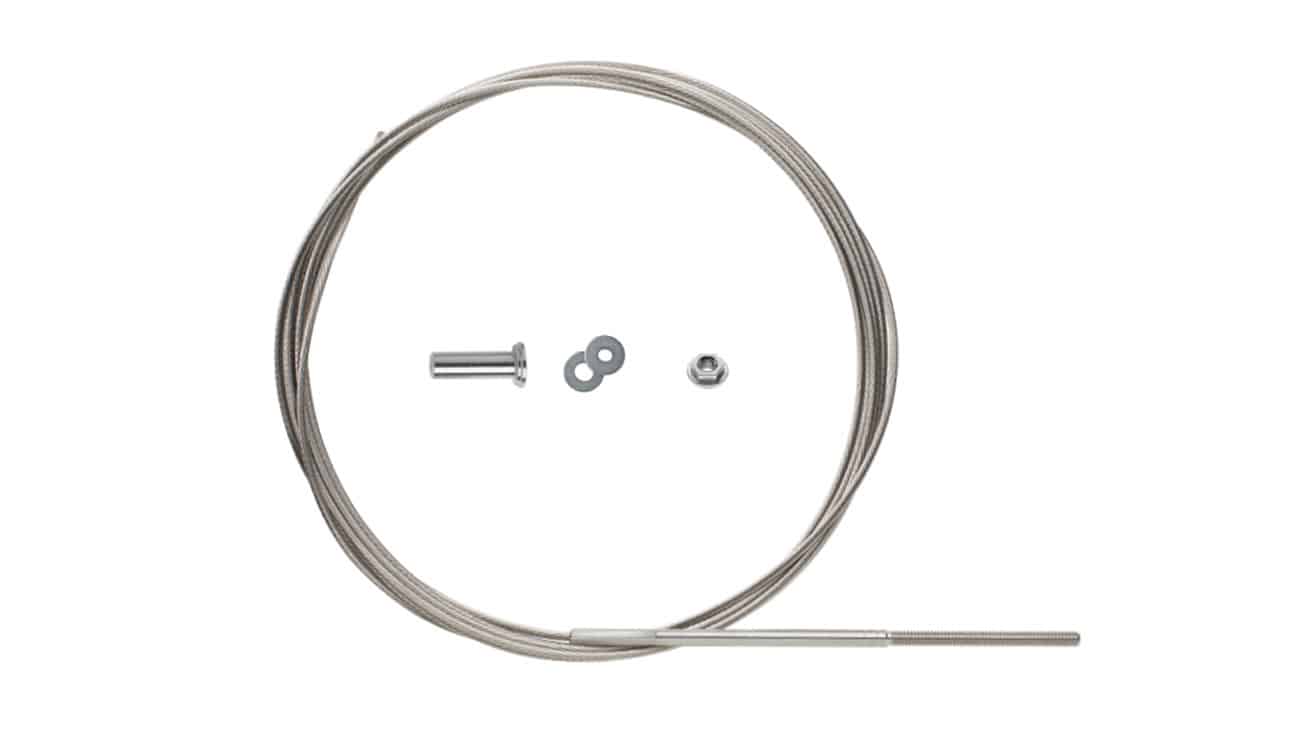

Each Kit has everything you need to attach and tension one run of cable.

Image Gallery

Need inspiration? Browse our image gallery for ideas to use with your next interior or exterior railing project.

VisualBuilder

Imagine before you build. Use our Feeney visualization tool and envision how Feeney can help you create your perfect outdoor space or dream deck.

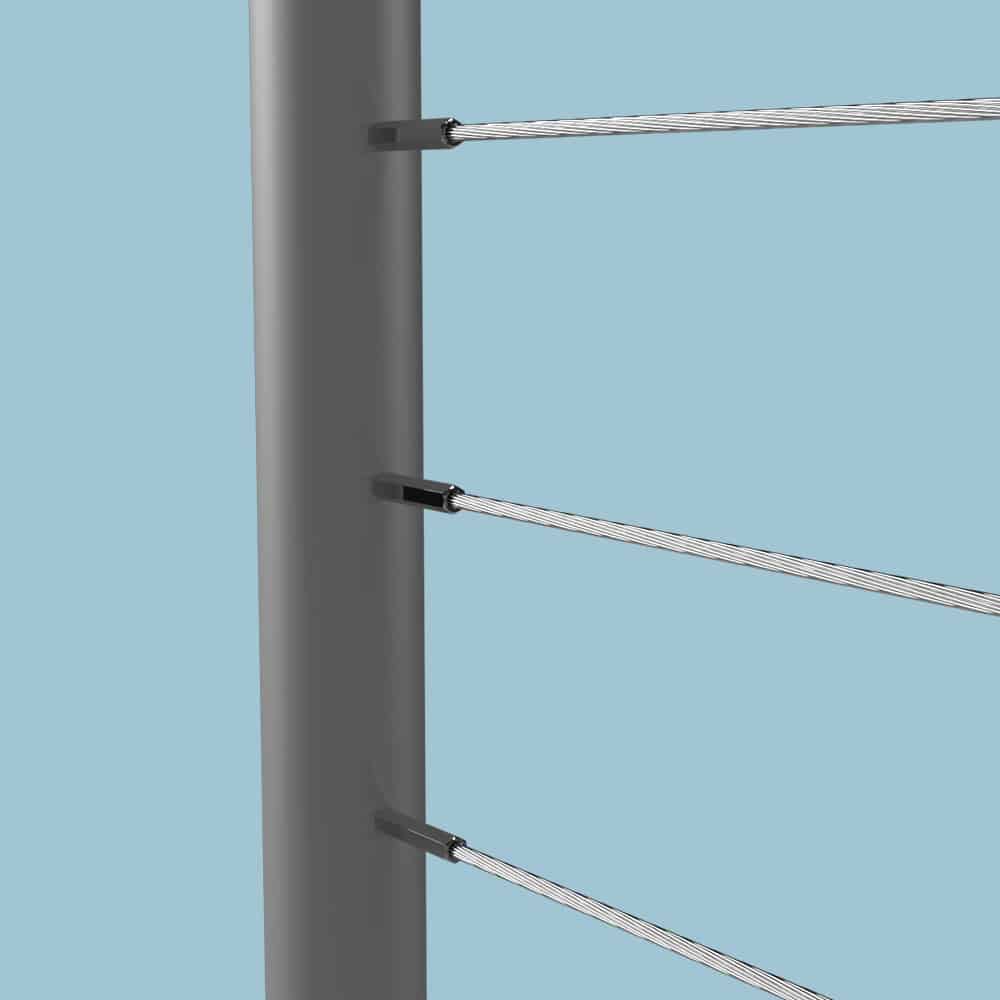

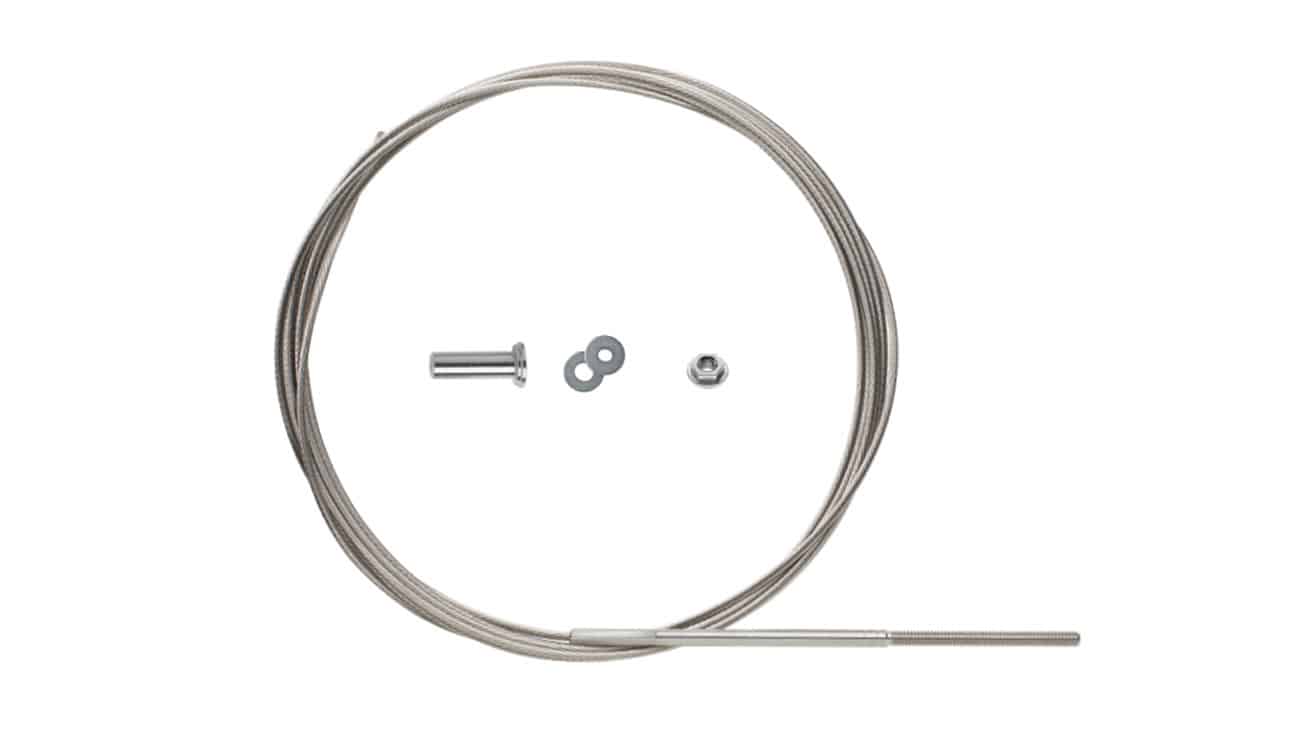

CABLERAIL KITS (6200 series) – 1/8″ (Metal)

Residential kits come in lengths of 5′ to 50′, includes a 4-1/4″ Threaded Terminal pre-attached to one end of the 1/8” cable.

CABLERAIL KITS

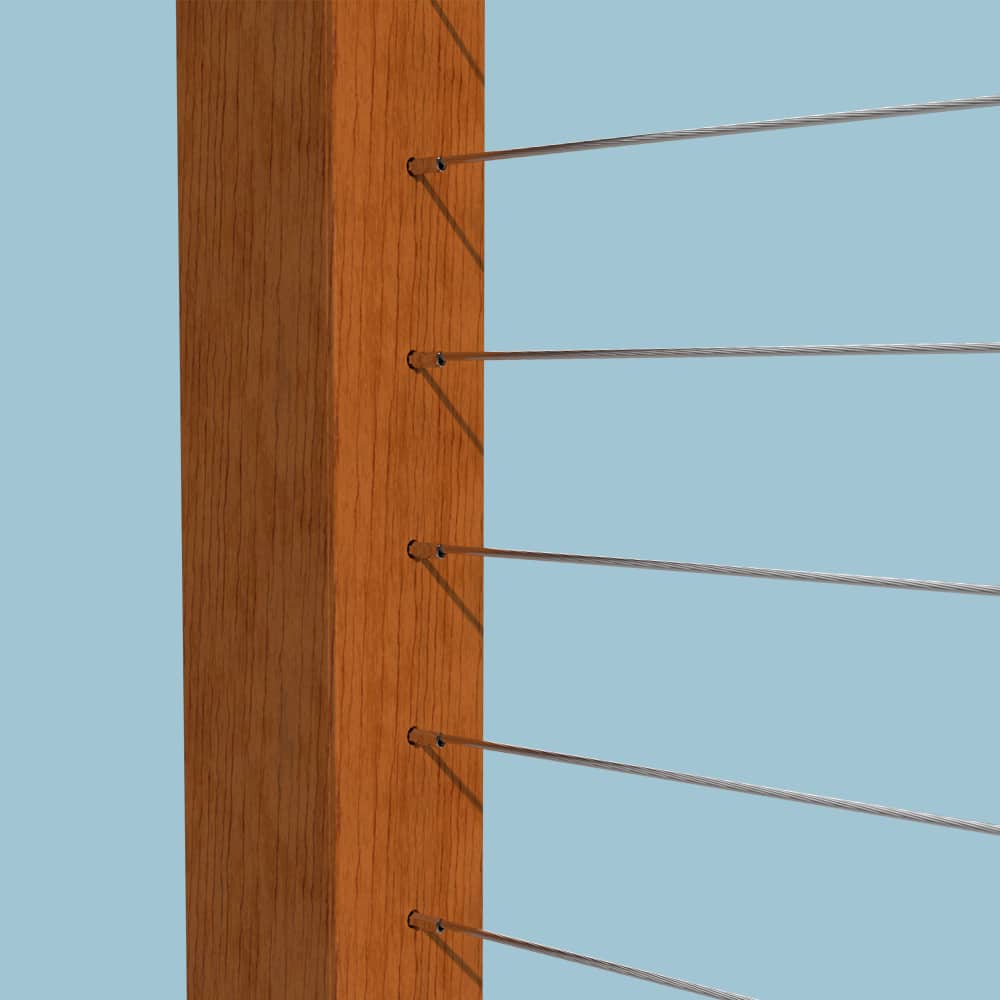

(6300 series) – 1/8″ (Wood)

Residential kits come in lengths of 5′ to 50′, includes a 7-1/2″ Threaded Terminal pre-attached to one end of the 1/8” cable.

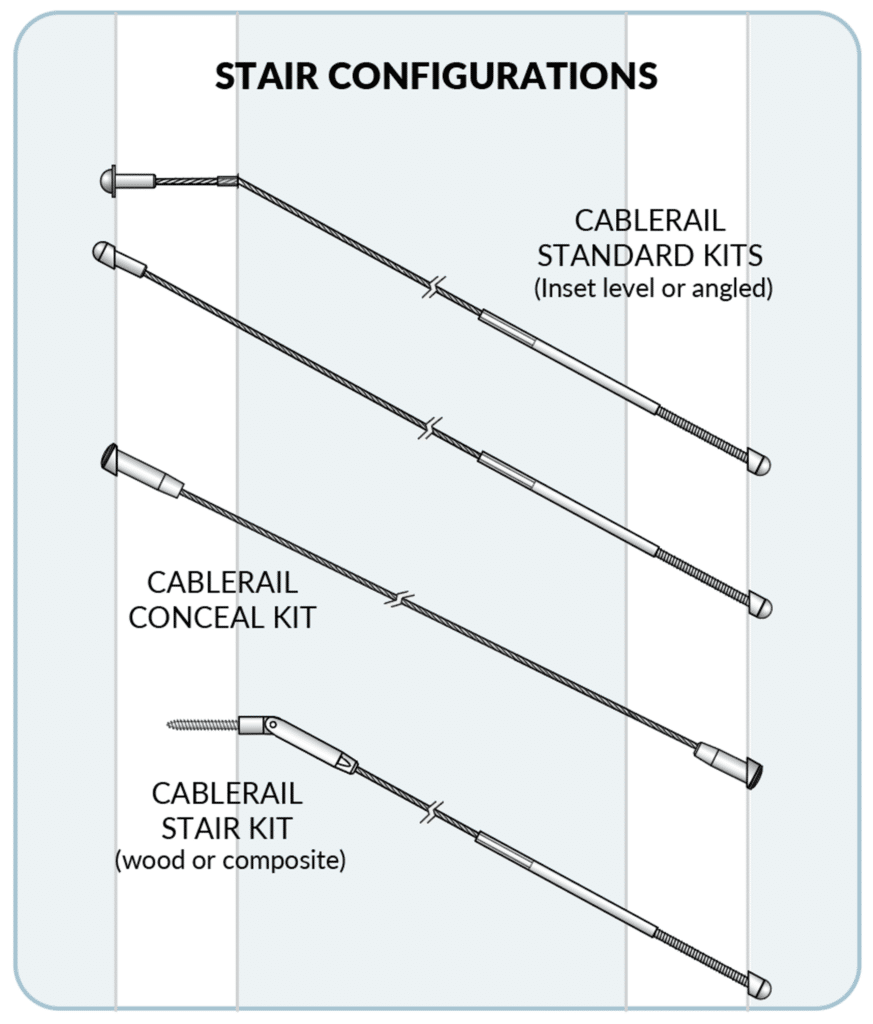

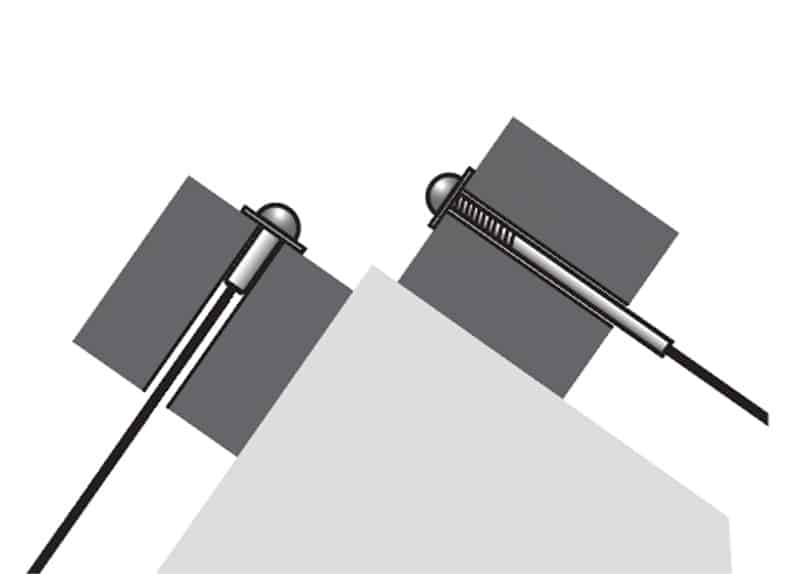

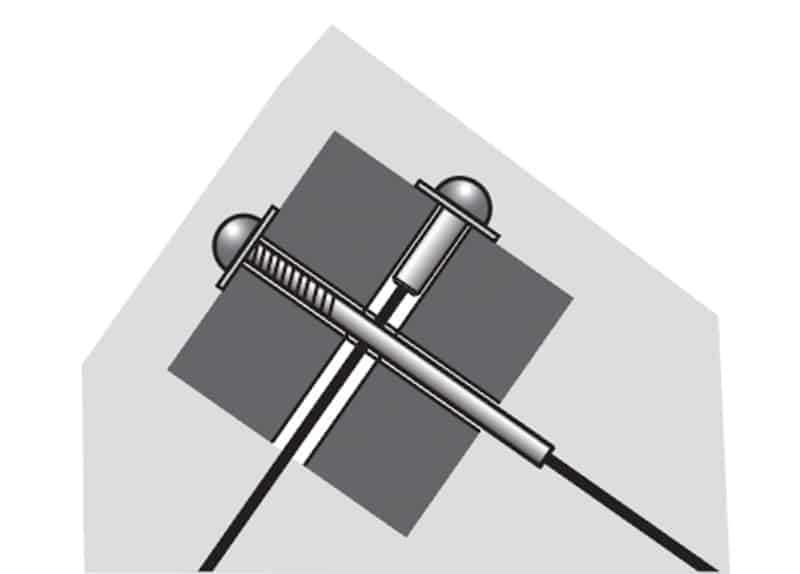

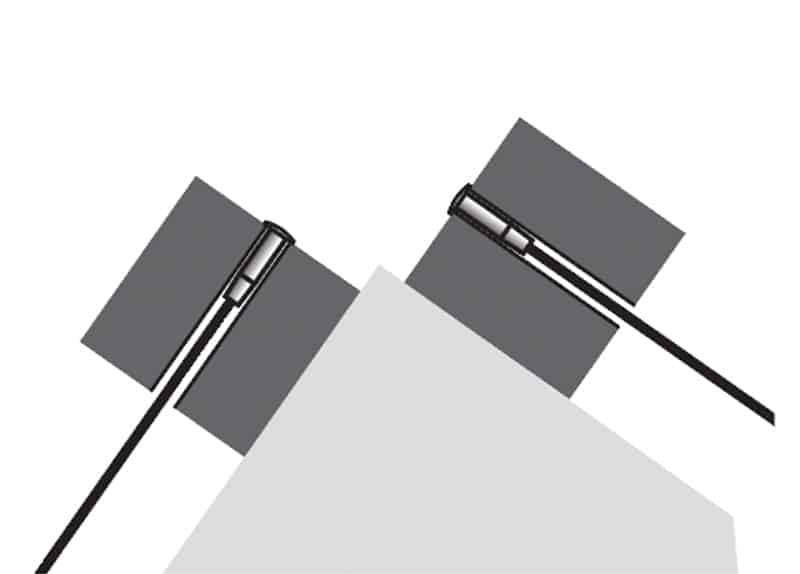

CABLERAIL STAIR KITS (6500 series) – 1/8″ (Wood)

For wood posts, includes a Quick-Connect® Pivot fitting along with the Threaded Terminal attached to a 20′ length of 1/8″ cable.

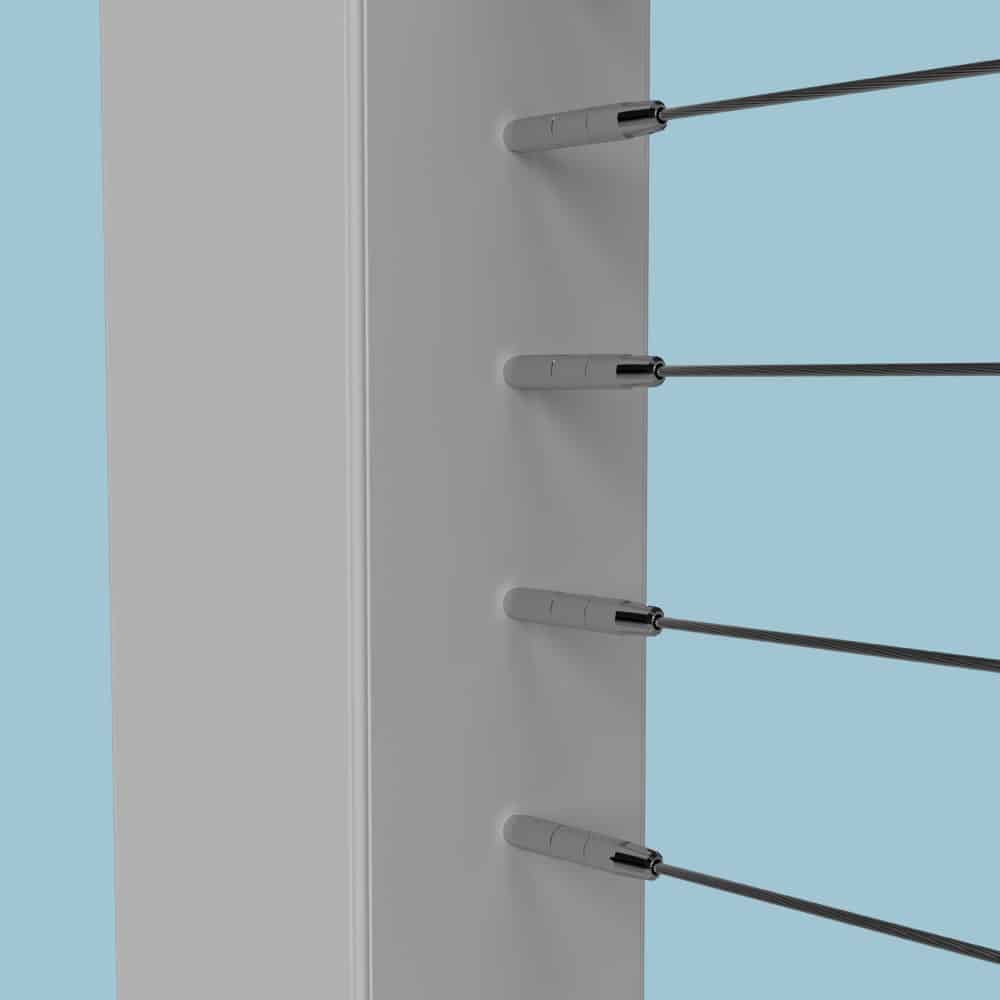

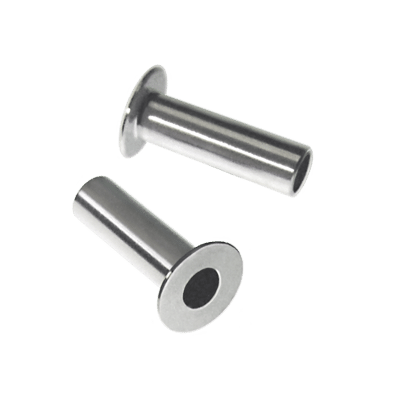

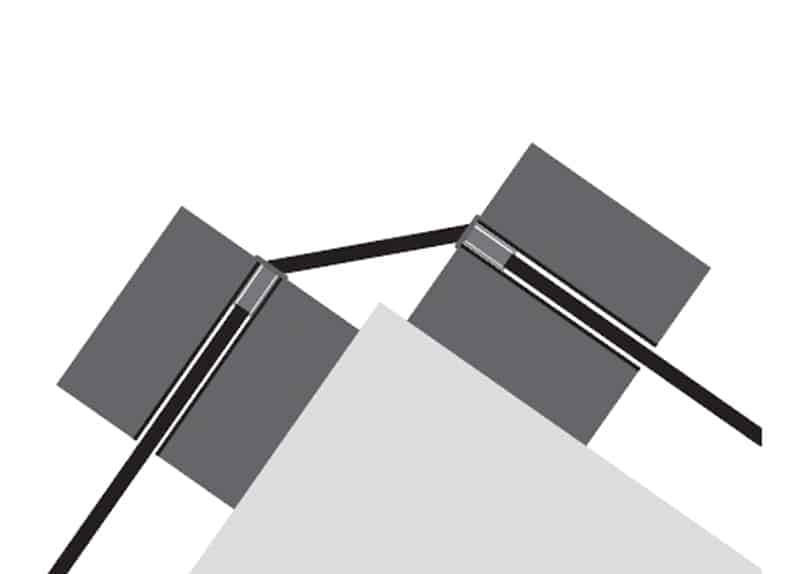

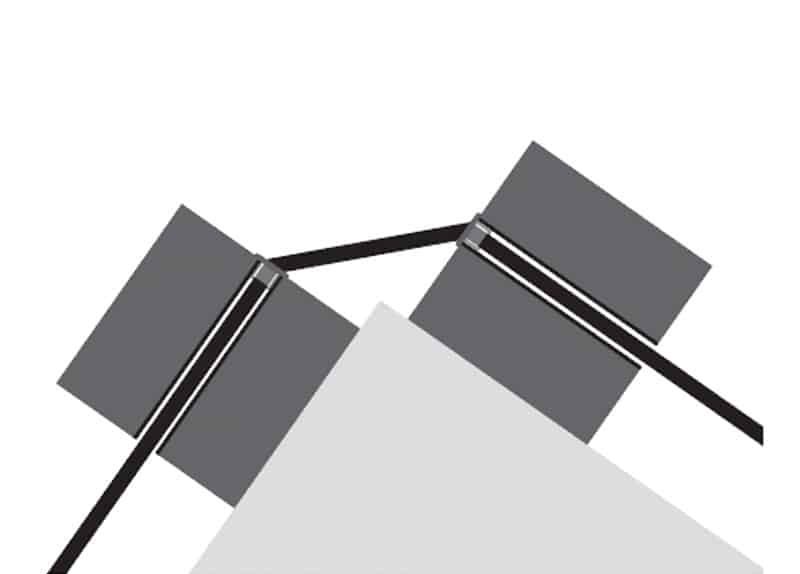

CABLERAIL CONCEAL KITS (100 series) – 1/8″

A low-profile alternative to our original CableRail Kits – works for both wood and metal frames.

CABLERAIL KITS (6700 series) – 3/16″ (Metal)

Residential & Commercial kits come in lengths of 5′ to 50′, includes a 4-1/4″ Threaded Terminal pre-attached to one end of the cable.

CABLERAIL KITS (6800 series) – 3/16″ (Wood)

Residential & Commercial kits come in lengths of 5′ to 50′, includes a 7-1/2″ Threaded Terminal pre-attached to one end of the cable.

CABLERAIL KITS (6900 series) – 1/4″ (Metal)

Heavy duty/industrial kits come in lengths of 5′ to 50′, includes a 4-1/4″ Threaded Terminal pre-attached to one end of the 1/4″ cable.

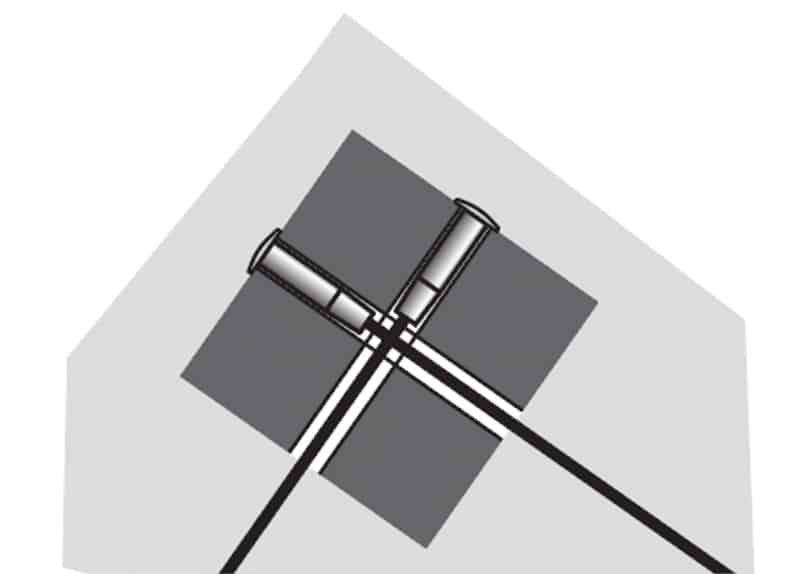

CABLERAIL ATR KITS (2000 series)

Includes our specially designed All-Thread Receiver (ATR), in lengths of 1 inch to 3 feet, for use with oversize posts, for 1/8” cable.

CableRail ATR Kits (4000 series)

Includes our specially designed All-Thread Receiver (ATR), in lengths of 1 inch to 3 feet, for use with oversize posts, for 3/16” cable.

FAQs

-

How far apart can I space the cables?

The International Building Code states that a 4-inch sphere cannot pass through any opening in your railing and since cable is non-rigid, the flex of the cable must be taken into account. We recommend spacing the cables no more than 3 inches apart to allow for possible cable deflection and to meet the intent of the code. Before starting a CableRail project, installers should always check with their local building department to see if there are any special local requirements for using and installing cable railings.

-

What’s the longest cable run I can have?

When using our standard CableRail Kits, we recommend that straight runs of cable (no corners or bends) should not exceed 70 feet. Runs with corner bends (using double corner posts) should not exceed 40 feet and should not have more than two corners per run. Maximum run lengths may be less if using CableRail Conceal Kits or other Quick-Connect® or swage-type fittings. Give us a call to confirm the maximum run lengths for your specific project.

-

Why would I consider using intermediate pickets on my railing frame?

Intermediate pickets (also referred to as vertical spacers) are used as a frame design option to replace some of the larger, bulkier intermediate posts, in order to achieve a more open railing design. They are non-structural members and are only intended to maintain cable spacing and minimize possible cable deflection. Intermediate pickets are typically made from 1″x 2″ or 2″x 2″ wood strips, 1″ copper water tubing, or 1/4″ thick metal flat bar, but other slender materials may be used. You may also use our pre-drilled, powder-coated Aluminum Intermediate Pickets (accessory items #7648 & #7649).

-

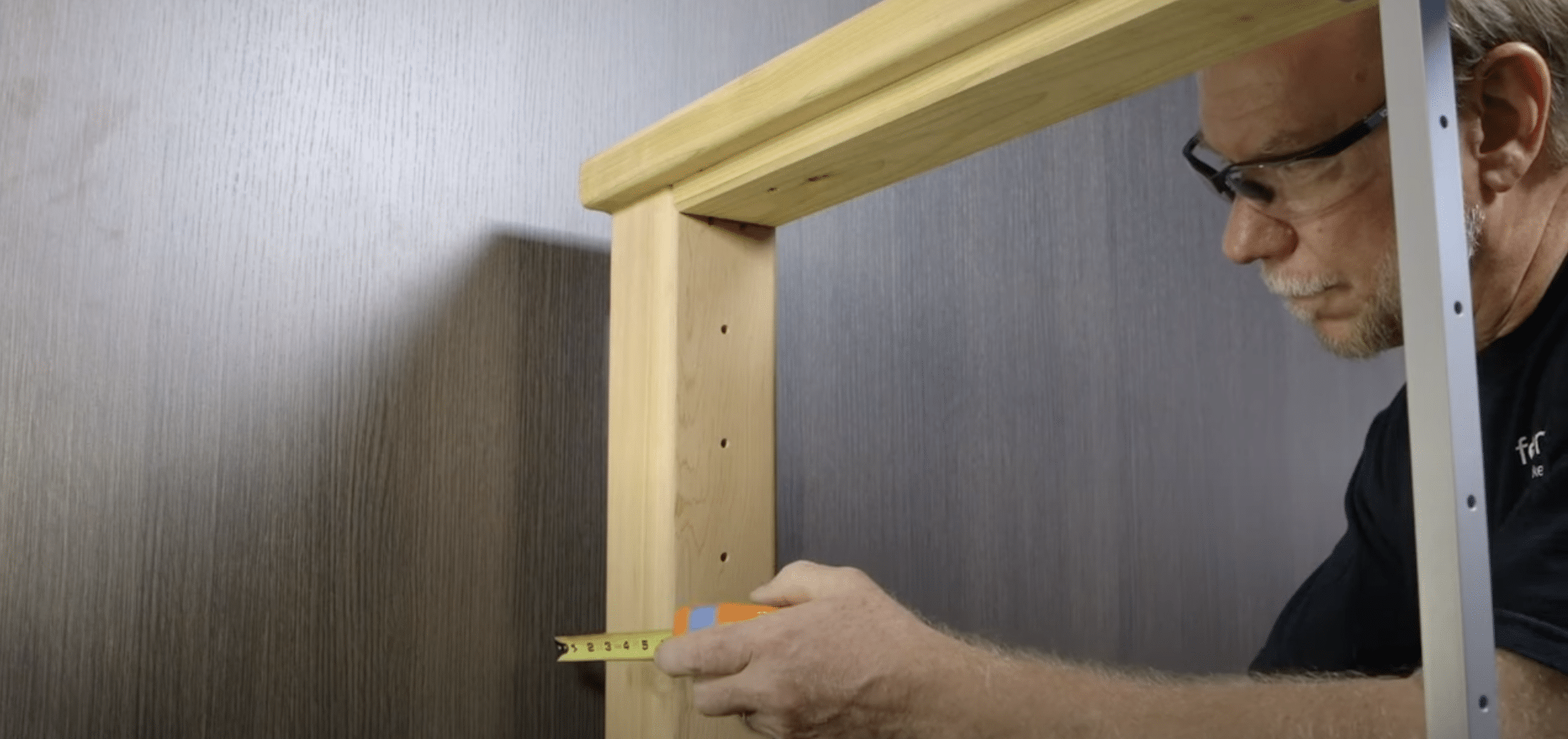

If there is no access to drill through an end post, can the fittings be attached to the face of the post or wall?

Not with the standard CableRail Kits. The cable fittings used with the standard Kits are attached by drilling holes all the way through the end posts and the fittings then bear up against the outside faces of the posts. If your railing frame runs into the face of a post/wall, you have two options: 1 ) install an end post three-to-four inches away from the wall face to allow access for attaching the standard Kit cable end fittings or 2) select fittings and cable from our CableRail Fittings or custom hardware options on our website to create assemblies specifically designed for wall or post face mounting. For recommendations and assistance, please give us a call at 1-800-888-2418.